designed and constructed in Fanniroo co.

Zero Liquid Discharge

What is ZLD?

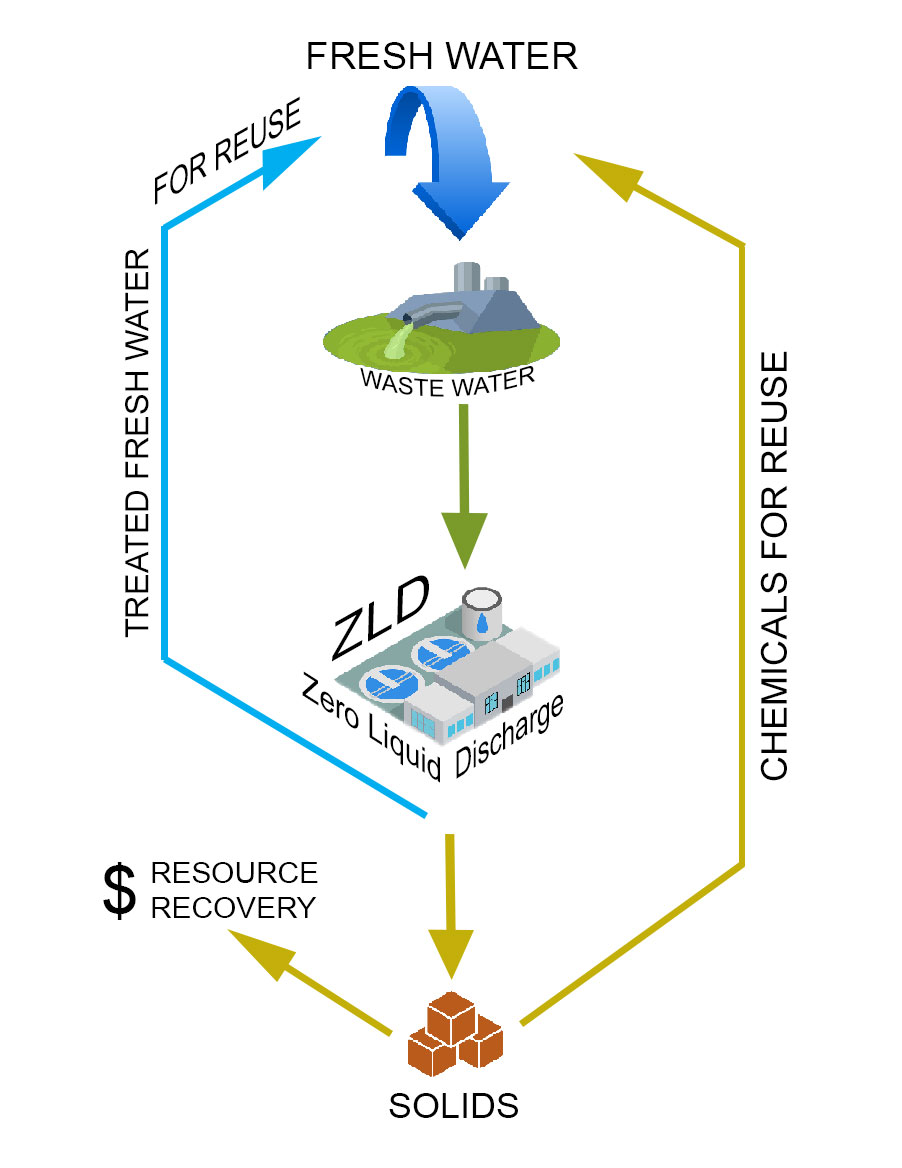

As the name implies, ZLD aims to remove any and all liquid waste discharged by the system. Liquid waste can contaminate natural water supplies, disrupt the ecosystem and cause other environmental problems. By recovering all the water in a waste water stream, not only the problem of waste water is eliminated, it also creates a new sustainable source of water for municipal or industrial purposes.

ZLD in Fanniroo - short intro

Why ZLD?

With the growing population of the world and the ever-shrinking water supplies due to contamination or overuse, humanity needs to find new, alternative sources of water. With ZLD, any source of water can become a suitable source of potable or industrial water.

World governments are also tightening environmental regulations to combat the damage done by various types of contaminated discharge. ZLD can reduce the liquid waste water to nothing, enabling the water to be reused, and producing solid waste such as salts that can be utilized or disposed of safely.

ZLD can bring about new investment opportunities for places with scarce water supplies and reduce the environmental impact of existing industries.

Fanniroo Co. and ZLD

Established in 1992, Fanniroo has designed, constructed, and commissioned several water desalination plants in various locations in Iran, and the middle-east; based on MED and RO technologies. As a pioneer of water desalination technology in Iran, Fanniroo is committed to research and development of new, cutting edge ZLD technologies, including but not limited to different membrane and thermal processes.

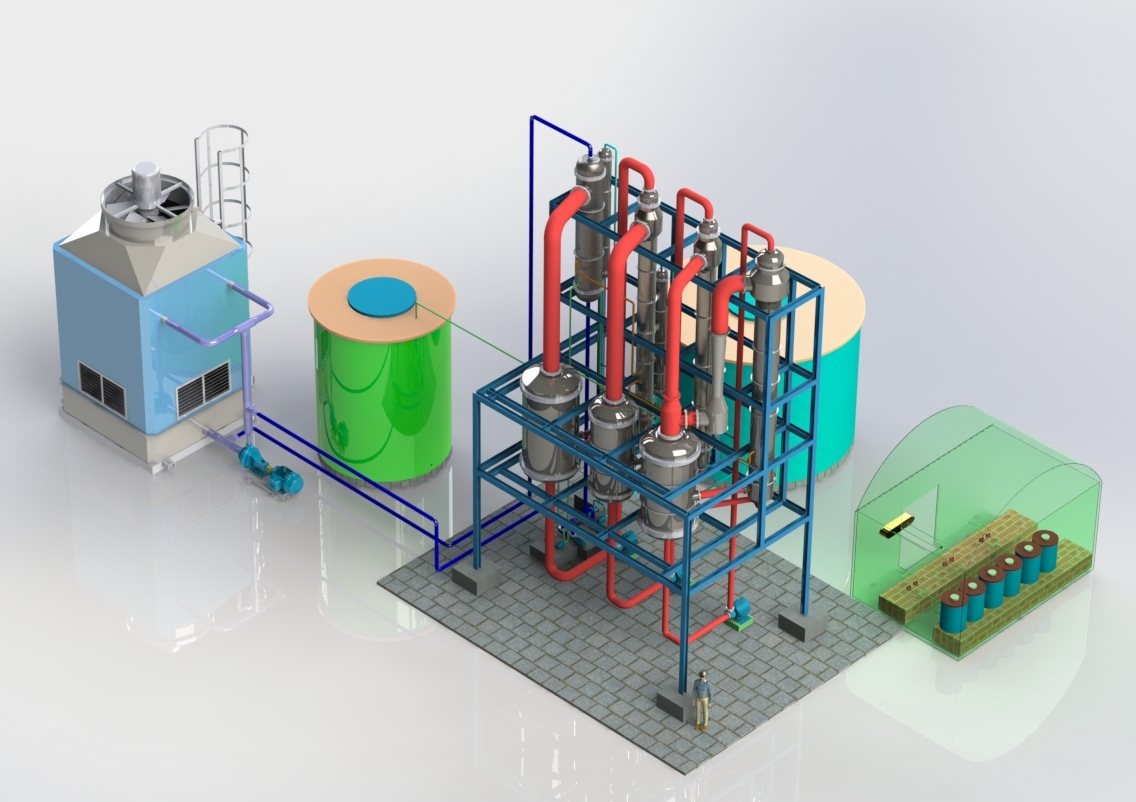

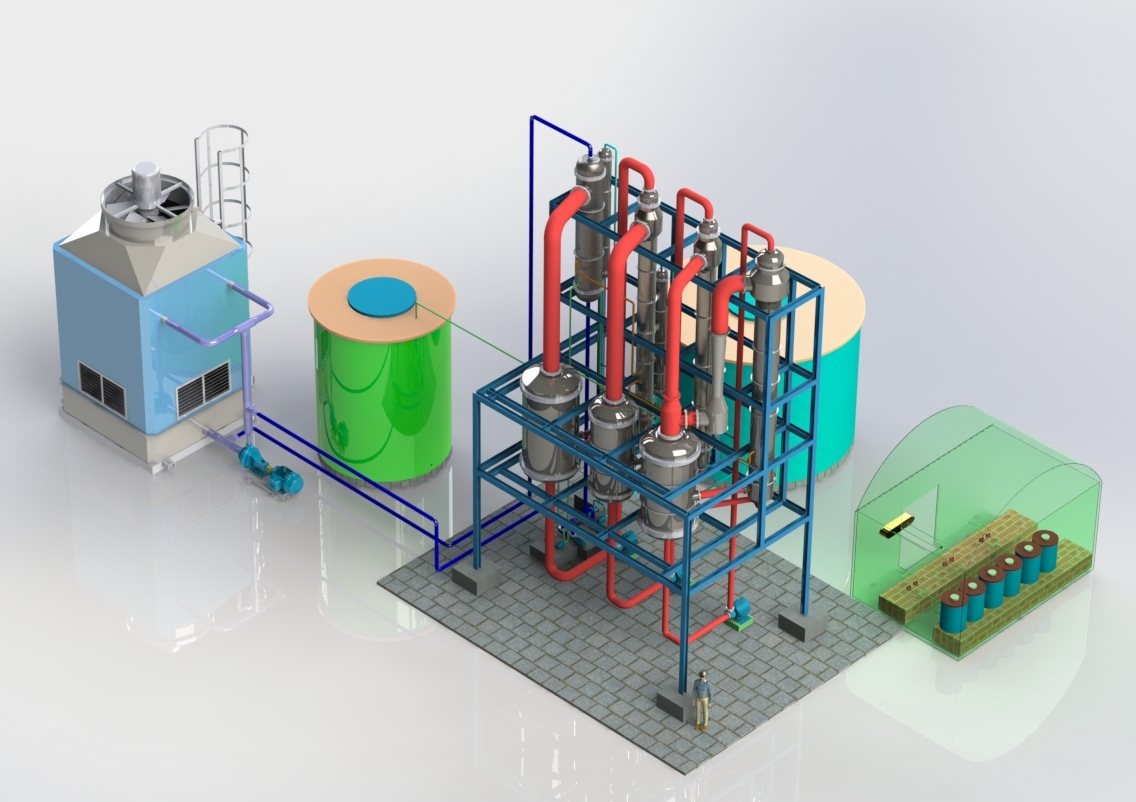

Fanniroo ZLD Pilot plant

So far Fanniroo has designed and constructed two pilot plants based on Falling Film Evaporation and Forced Circulation Crystallization technologies. All of our designs are developed through our proprietary ZLD software, able to design the entire process and intelligently determine heat transfer area, the recommended number of steps, and other process variables. With the experience gathered from these projects, as well as studying the current trend of ZLD technology in the world, we are confident to able to deliver projects competing with the biggest names in ZLD.

ZLD Technologies

According to their working principle, ZLD technologies can be categorized in several different categories, most important of which are membrane and thermal.

Membrane technologies like UF, NF and RO use high pressure to push the waste water through a membrane that prevents impurities from passing. Membrane processes have lower energy consumption, but are unsuitable for streams with extremely high percentage of impurities as system pressure can rise to unsustainable values.

ZLD 3D model with BC – prototype

Thermal technologies use heat to evaporate the wastewater, and condense the vapor as pure water ready for reuse. Thermal technologies can handle wastewater with much higher amount of impurities, but have higher energy consumption, and are more susceptible to scaling and corrosion. Currently, evaporation and crystallization are the heart of ZLD technology, with true ZLD being out of reach without them.