Falling Film Evaporation

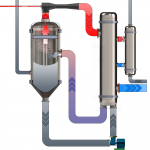

Thermal technologies are the heart of any ZLD system. Falling Film Evaporators use a thin film to provide high heat transfer and evaporation rate.

Falling Film Evaporators are best suited to concentrate streams of low-scaling materials and even heat sensitive materials due to short residence time in the heating area. They can be used before crystallization process to concentrate the stream for the simplification of the process.

Vapor Recompression

Vapor Recompression can provide an effective method to recycle the motive energy for better process efficiency. Vapor Recompression can either be Thermal (TVR), or Mechanical (MVR). Vapor Recompression can easily enhance energy consumption of the plant by 30 to 50%.

TVR

Thermal Vapor Recompression uses a thermocompressor to reuse the generated vapor and improve process efficiency. TVR has the advantage of easier, cheaper design and manufacturing, no moving parts and thus lower maintenance costs, as well as smaller local footprint. Vacuum temperature operation is more feasible with TVR systems, lowering overall process temperature, and resulting in lower temperature related failures.

However, TVR system needs a source of live, high pressure steam to drive the thermocompressor. If such a source is not available close to the site, Mechanical Vapor Recompression can be used alternatively.

MVR

Mechanical Vapor Recompression uses an electrically driven compressor to recycle energy from the generated vapor. MVR systems are more difficult and costly to produce, but they don’t need a source of live steam.

MVR systems are best suited for operation at atmospheric temperatures, and may be powered by renewable energy sources, lowering overall carbon footprint.

Multiple effects

Falling film evaporators can be designed with multiple effects. This is beneficial in situations where energy is expensive, as several effects can effectively recycle the vapor generated in the previous effects as the motive energy for the subsequent effects. This process can be enhanced further with the usage of Thermal Vapor Recompression, to recycle the energy even more effectively.

Fanniroo and Falling Film Evaporators

Fanniroo Co. can design falling evaporators of various capacities and stages, as well as various heat recovery methods, such as MVR (Mechanical Vapor Recompression) and TVR (Thermal Vapor Recompression) through our proprietary ZLD software. Fanniroo Co. is experienced in using different types of material for construction to meet the specific criteria needed by any type of streams.

Benefits of Falling Film Evaporators:

- High quality recovered water, suitable for industrial or municipal reuse

- Suitable for heat sensitive products

- Large capacities with various configurations

- Fully automatic control mechanism, constant monitoring by software

- Low energy consumption, up to 25 kWh/m3 with MVR or TVR heat recovery

Leave a Reply

Want to join the discussion?Feel free to contribute!