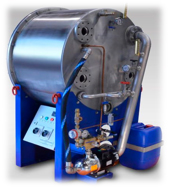

Fresh Water Distiler (FWD)

Fresh Water Distiler used to produce fresh water from seawater based on vaccum distillation principle. The most important feature of this method is its portability. For this reason, it has a wide application in ships, hotels and oil platforms. There are two conventional types of FWD; single or multi-stage. The available Fresh Water Distilers in the market are likely single or two-stage. Single-stage freshwater distillers require a relatively large amount of energy to operate, but are less expensive than their multi-stage modules. Two-stage distilers are likely used for high capacity and in order to reduce energy consumption.

- Process description of a two-stage FWD

A two-stage fresh water distiler consists of three types of titanium plate exchangers that are located in separate chambers with various rates of vaccum. The heat required for the first stage is provided with hot water (steam can also be used instead of hot water as a heat source).

The upper plate bundle, which is called first stage, evaporates the feed water under a vaccum of 70 per cent. The steam that is produced from the first stage of evaporation unit passes through demisters and enters the next stage. The brine evaporates rapidly in the second chamber under a vacuum of 90%. Saving energy in this system can be as much as possible. The energy consumption is decreased considerably by increasing the number of evaporation stages and heat transfer surface. Therefore, desalinated water can be produced with the least amount of energy consumption. The condenser is located in the second chamber; it is cooled with a jet of cold sea water inlet through the ejector. This ejector has a double function; extraction of the brine out of the housing and vacuum creation by exhaust of the Non-Condensable Gases (NCG). The produced fresh water of both stages enters to Flash Tank and storage tank, respectively.

- Energy Supply

- Steam

- Hot Water

- Major components

- Separator chamber

- Heat Exchanger (plate or shell&tube)

- Hydro-Ejector

- Ejector pump

- Fresh water pump

- Salinometer

- Control panel

- Features

- Simple, compact design

- Portable

- Ability to increase or decrease unit capacity due to variations of hot water flow rate or number of heat exchanger plates

- High performance system

- Increasing the heat transfer coefficient

- Convenient maintenance

- Convenient separation of plates for inspection and repair