The desalination system which is described in this section is designed based on Multi-Effect type Desalination with thermal vapour compression. A reasonable technology considering long life operation, utilizing sea water or any type of contaminated water to produce very pure water in order to drinking and industrial purposes.

In the MED (Multi Effect Desalination) method, evaporation and distillation are performed under high vacuum conditions.

The inlet water is spread over the effect tubes by a proper distribution system and, a part of it is evaporated by the steam passing through the tubes. The steam produced from the first effect of evaporation unit passes through demisters, and enters the horizontal tubes in the next effect.

By distributing water over these tubes, a portion of this water is evaporated while the flowing steam inside the tubes is condensed.

Read More about MED Process …

The vapor produced enters the next effect, and the process will continue. Saving energy in this system can be as much as possible. The energy consumption is decreased considerably by increasing the number of evaporation effects and heat transfer surface; therefore, desalinated water can be produced with the least amount of energy consumption. The maximum temperature of brine water in this method is 70oC which results the minimum possible scale and corrosion.

Advantages:

Currently the world’s largest designed desalination unit with the lowest product water cost, utilizes MED method equipped with the last technological developments and waste heat recovery method.

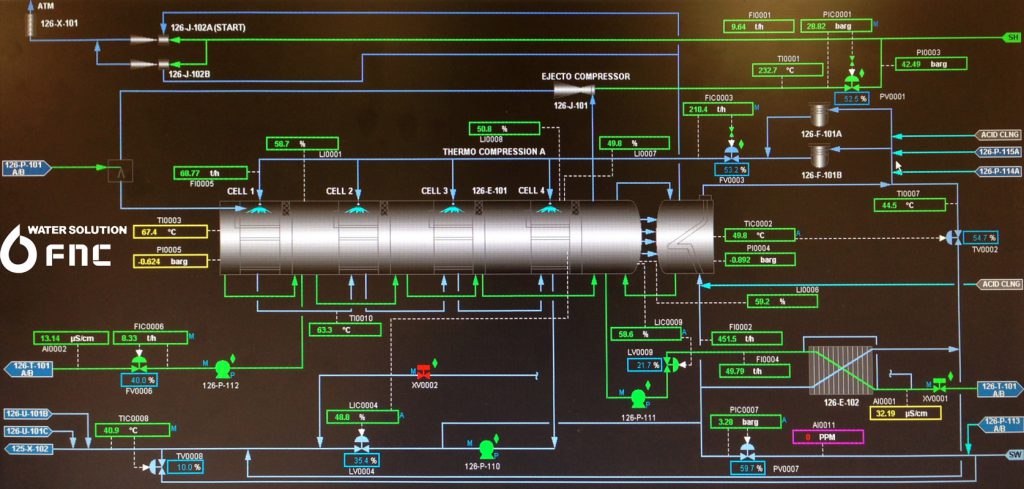

Monitoring Sample; one of our MED Plants.